Thermistor Principle:

We are all known that a resistor is an electrical component that limits the amount of current flows through a circuit. Thermistor is special type of resistor, whose resistance varies more significantly with temperature than in standard resistors. Generally, the resistance increases with the temperature for most of the metals but the thermistors respond negatively i.e. the resistance of the thermistors decrease with the increase in temperature. This is the main principle behind thermistor. As the resistance of thermistors depends on the temperature, they can be connected in the electrical circuit to measure the temperature of the body.

Thermistors are mainly used as temperature sensors, inrush current limiters, self-resetting over-current protectors and self-regulating heating elements. A thermistor is made from a semiconductor material. It is shaped into a disc, a rod or a bead. Bead thermistors may be only a few millimetres in diameter. Some bead thermistors have the bead enclosed in a glass capsule.

The symbol of Thermistors can be represented as follows:

Types of Thermistors:

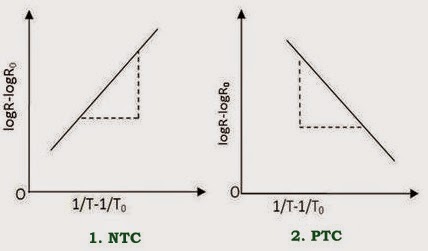

There are mainly 2 types of thermistors namely Positive-temperature coefficient (PTC) and Negative-temperature coefficient (NTC).

Positive Temperature Coefficient (PTC):

PTC thermistors increase their resistance as the temperature rises. The relationship between resistance and temperature is linear, as expressed in the following equation: deltaR = k(deltaT) where deltaR is the change in resistence, deltaT is the change in temperature and k is the temperature coefficient. When k is positive, it causes a linear increase in resistance as the temperature rises.

PTC Uses: PTC thermistors can be used in place of fuses for circuit protection. As the circuit heats up, resistance increases to prevent overload. They are also used as timing devices in televisions. When the unit is switched on, the degaussing coil is activated to eliminate the magnetic field; the thermistor automatically switches it off when the temperature reaches a certain point.

Negative Temperature Coefficient (NTC):

Many NTC thermistors are made from a pressed disc or cast chip of a semiconductor such as a sintered metal oxide. They work because raising the temperature of a semiconductor increases the number of electrons able to move about and carry charge – it promotes them into the conduction band. The more charge carriers that are available, the more current a material can conduct. This is described in the formula:

I = n.A.v.e

Where

I = electric current (amperes)

n = density of charge carriers (count/m³)

A = cross-sectional area of the material (m²)

v = velocity of charge carriers (m/s)

e = charge of an electron (e=1.602 \times 10^{-19} coulomb)

The current is measured using an ammeter. Over large changes in temperature, calibration is necessary. Over small changes in temperature, if the right semiconductor is used, the resistance of the material is linearly proportional to the temperature. There are many different semiconducting thermistors with a range from about 0.01 kelvin to 2,000 kelvins (-273.14 °C to 1,700 °C)

NTC Uses: NTC thermistors, on the other hand, are used as current-limiters and temperature monitors in digital thermostats and automobiles.

Testing of a Thermistor:

This is just a sample and rough test for basic understand about how to test a thermistor. The analog multimeter has to be kept in resistance mode. The multimeter terminals are to be connected to the thermistor leads. We need not concentrate on polarity here. Now, heat the thermistor by moving the heated soldering iron tip to it. Now you can observe that the multimeter reading increases or decreases smoothly depending o whether the thermistor under test is PTC or NTC. Of course, it happens only for a healthy thermistor.

For faulty thermistors, we may observe the following things.

- The change in reading will never be smooth or there will not be any change at all.

- For a short thermistor, the meter reading will be always zero where as for an open thermistor the meter reading will be always infinity.

As I mentioned earlier, it is just a rough test. For perfect confirmation, we need to follow some process of measuring the temperature and corresponding resistance reading and that has to be compared with the thermistor’s temperature-resistance characteristics provided by the manufacturer.

Thermistor characteristics:

As just mentioned above, resistance increase with increase in temperature for PTC and resistance decrease with increase in temperature for NTC.

The thermistor exhibits a highly non-linear characteristic of resistance vs temperature.

PTC thermistors can be used as heating elements in small temperature controlled ovens. NTC thermistors can be used as inrush current limiting devices in power supply circuits. Inrush current refers to maximum, instantaneous input current drawn by an electrical device when first turned on. Thermistors are available in variety of sizes and shapes; smallest in size are the beads with a diameter of 0.15mm to 1.25mm.

There are two fundamental ways to change the temperature of thermistor internally or externally. The temperature of thermistor can be changed externally by changing the temperature of surrounding media and internally by self-heating resulting from a current flowing through the device.

The dependence of the resistance on temperature can be approximated by following equation,

Where,

R is the resistance of thermistor at the temperature T (in K)

R0 is the resistance at given temperature T0 (in K)

β is the material specific-constant

R0 is the resistance at given temperature T0 (in K)

β is the material specific-constant

The material specific-constant of a NTC thermistor is a measure of its resistance at one temperature compared to its resistance at a different temperature. Its value may be calculated by the formula shown below and is expressed in degrees Kelvin (°K).

Thermistor Applications:

- PTC thermistors were used as timers in the degaussing coil circuit of most CRT displays. A degaussing circuit using a PTC thermistor is simple, reliable (for its simplicity), and inexpensive.

- We can also use PTC thermistors as heater in automotive industry to provide additional heat inside cabin with diesel engine or to heat diesel in cold climatic conditions before engine injection.

- We can use PTC thermistors as current-limiting devices for circuit protection, as replacements for fuses.

- We can also use NTC thermistors to monitor the temperature of an incubator.

- Thermistors are also commonly used in modern digital thermostats and to monitor the temperature of battery packs while charging.

- We regularly use NTC thermistors in automotive applications.

- NTC thermistors are used in the Food Handling and Processing industry, especially for food storage systems and food preparation. Maintaining the correct temperature is critical to prevent food borne illness.

- NTC thermistors are used throughout the Consumer Appliance industry for measuring temperature. Toasters, coffee makers, refrigerators, freezers, hair dryers, etc. all rely on thermistors for proper temperature control.

- We can regularly use the Thermistors in the hot ends of 3D printers; they monitor the heat produced and allow the printer’s control circuitry to keep a constant temperature for melting the plastic filament.

- NTC thermistors are used as resistance thermometers in low-temperature measurements of the order of 10 K.

- NTC thermistors can be used as inrush-current limiting devices in power supply circuits.

Get an idea about the following concepts also:

0 commentaires:

Enregistrer un commentaire